Single point dressers

Single point diamonds are suitable for both dressing and profiling of abrasive wheels. Maintaining a consistently high level of quality, Sorma offers two different categories of diamond: industrial quality, with 2-3 points of good shape, and excellent quality, with 4-6 points of good shape and free from inclusions or fractures. The stone used has a significant influence on the life of the tool and the result of the dressing.

Profile dressers

These Sorma tools are produced with high quality stones finished in the shape of a chisel or cone. They are used for high precision profiling, mainly with a copying device.

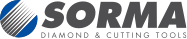

DM

The DM cluster dressers represent an economical alternative to single point diamonds of large carat size. In DM dressers, the dressing effort is spread over several points, allowing higher transverse feeds and more severe use of the tool. Suitable for dressing medium coarse-grained flat grinding wheels with high feed rates.

LD-R

The wheel dressers are particularly robust multiple diamond tip dressing, suitable for straight or angular dressing of grinding wheels for internal and external grinding. The tool is rotated on its axis every time a row of diamonds is worn out, presenting new points for processing. Excellent value for money compared to single point diamonds.

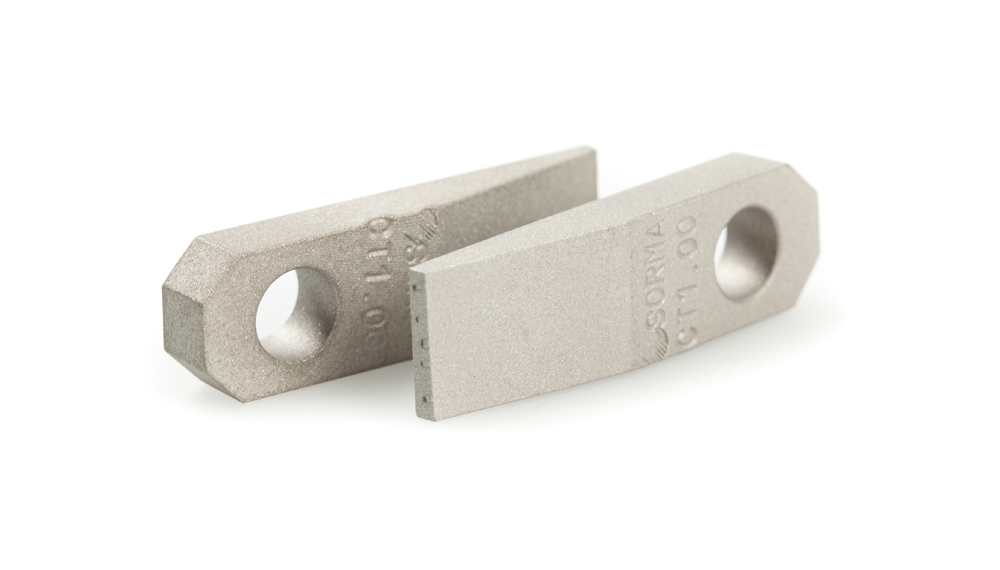

LD-C

Blade dressers contain elongated needle-like diamonds arranged in a multiplicity of overlapping layers. Due to their outstanding shape retention characteristics, they are mainly used for profiling, but can also be used for straight-line dressing operations. The surface finish can be easily changed on the grinding wheel by increasing or decreasing the translation. Sorma offers blade dressers with adjustable or rigid stems, supplied in two standard sizes for medium or large grinding wheels.

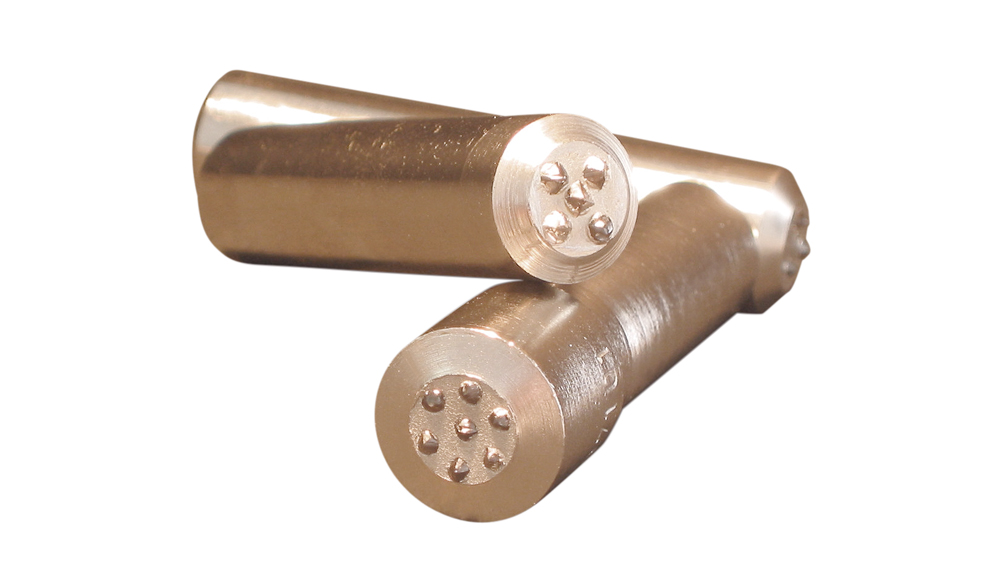

DI

Multipoint sintered dressers are among the most efficient tools in dressing and conditioning of abrasive wheels. They are manufactured by sintering diamond grits with metallic powders. The diamond grit dressers have been specifically designed for heavy-duty work and for the finishing of abrasive wheels on thread grinding machines, profiling machines as well as on round grinding machines and sharpeners.

HD

Available in two versions, the impregnated dressers allow the manual conditioning and dressing of abrasive wheels on equipment not provided with diamond holders, such as bench grinders.