Elastic bonded wheels

This revolutionary abrasive is obtained by mixing ceramic abrasive particles in a highly resistant synthetic rubber bond. The ceramic particles micro-fracture continuously exposing new sharp points and guaranteeing perfect processing until complete consumption. It is the best solution for light grinding, cleaning and polishing of moulds and dies. The flexibility of these tools guarantees processing without noise and vibrations while also minimising grinding dust.

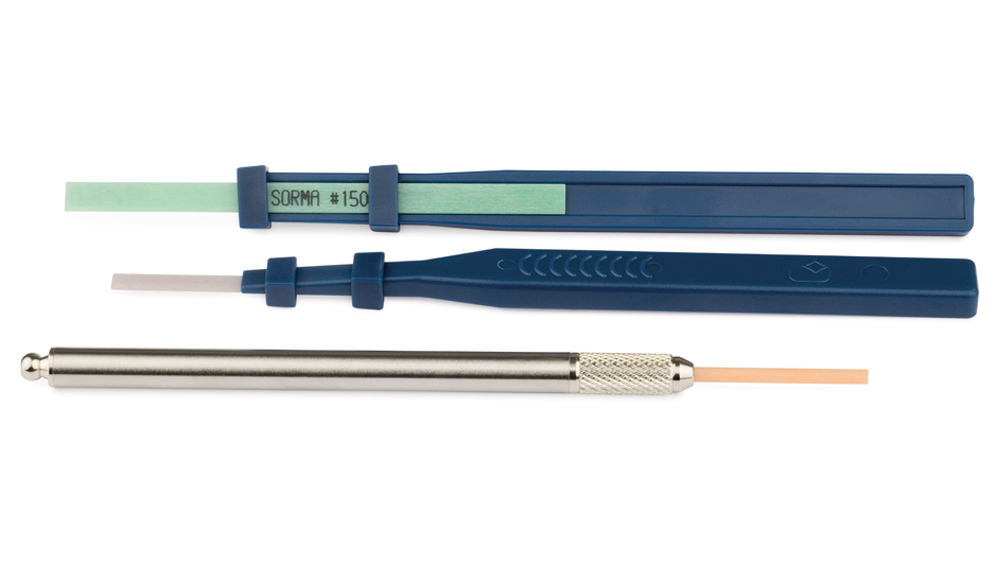

Nano-fibre ceramic stones

Nano-fibre ceramic polishing stones are excellent for removing scales from electro-discharge. Usable manually or with power files, Sorma stones represent the state of the art in the field of polishing stones and have significant advantages over traditional abrasive or other ceramic-fibres stones. The crystalline structure of the fibres guarantees repeatable and high quality surface finishes and the perfect adhesion of the fibres allows a resistance at the highest levels.

Diamond compound

The diamond paste is the ideal tool for performing quality micro-finishes on precision parts, moulds, dies and hard surfaces. Uniformity, purity and grit size selection of diamond powder come before anything else in the Sorma diamond paste production laboratories. The diamond compound is prepared with a specific carrier that holds the diamond particles in a permanent and uniform suspension. It is available in water or oil soluble type.

Super-fine lapping film

The range of Super-fine Sorma abrasive films ensures accurate and uniform finishes in a wide variety of applications. The careful selection of the shape and type of abrasive combined with the characteristics of the support make Sorma films much more effective than traditional abrasives on paper or canvas in high-precision machining.